In terms of process control, Duotaike adheres to the concept of "precision manufacturing, quality first" and exercises strict oversight starting from the raw material selection stage. The company has established long-term cooperative relationships with a number of suppliers with excellent reputation. Before all core materials are delivered to the factory, they must go through multiple inspection processes such as composition analysis and mechanical property testing to ensure that key indicators like material purity and strength meet the design standards, laying a solid foundation for subsequent production.

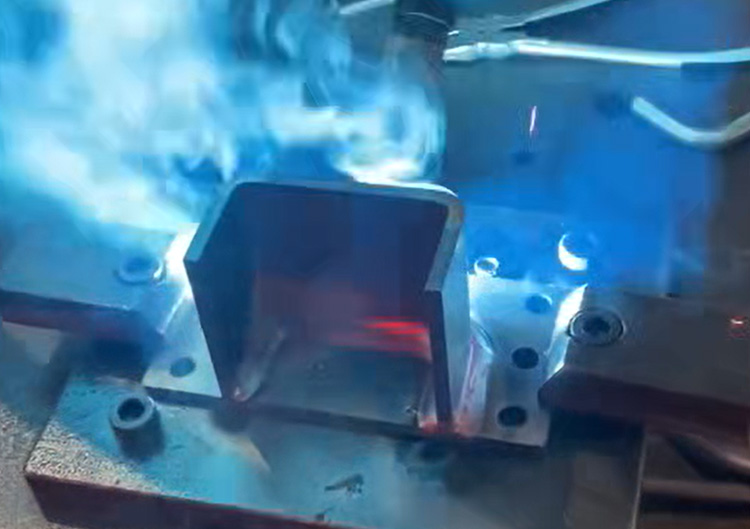

After entering the production phase, Duotaike adopts a combination of automated production lines and manual inspections to conduct strict supervision over each production process. All production equipment is equipped with precision monitoring systems, which can monitor processing data in real time. If deviations occur, the systems will issue timely warnings and make adjustments. At the same time, quality inspectors conduct random sampling tests on work-in-progress in a certain proportion, focusing on checking indicators such as dimensional accuracy and surface finish to ensure the stability of product quality.

To maintain its technological competitiveness, Duotaike continuously invests in R&D for process innovation. The company has established a professional R&D team that, based on market demands and industry development trends, constantly explores the application of new materials and new technologies. Through the improvement of production processes, the company has not only enhanced the durability of its products but also reduced energy consumption. These innovative practices have made the products more competitive in the market and gained recognition from customers.

Focus on us